Introduction

A research project on predictive maintenance and representation learning on sensor data collected from Volvo Trucks (Logged Vehicle Data: LVD).

Problem

The high dimensional nature of the LVD data is a serious problem since it demands increased storage capacities and processing power to be available on-board the vehicles. The goal of this thesis is to perform state of the art feature engineering and a novel way of compressing heavy truck data to a smaller size while still generating a more meaningful representation of the original data. In this way, we can save storage space, reduce

bandwidth, and quickly gauge the “health” of the trucks in real-time.

Results

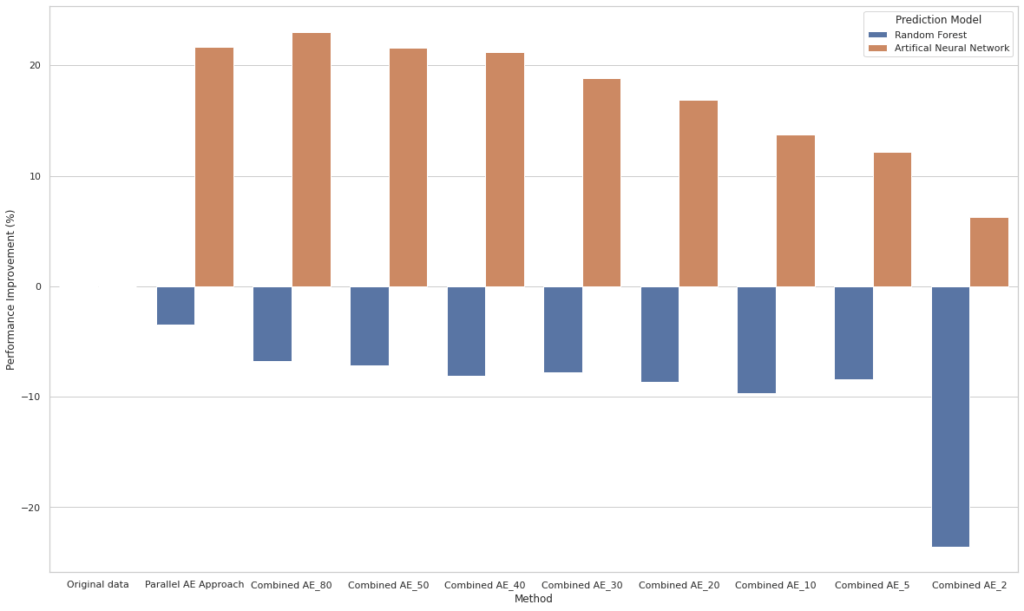

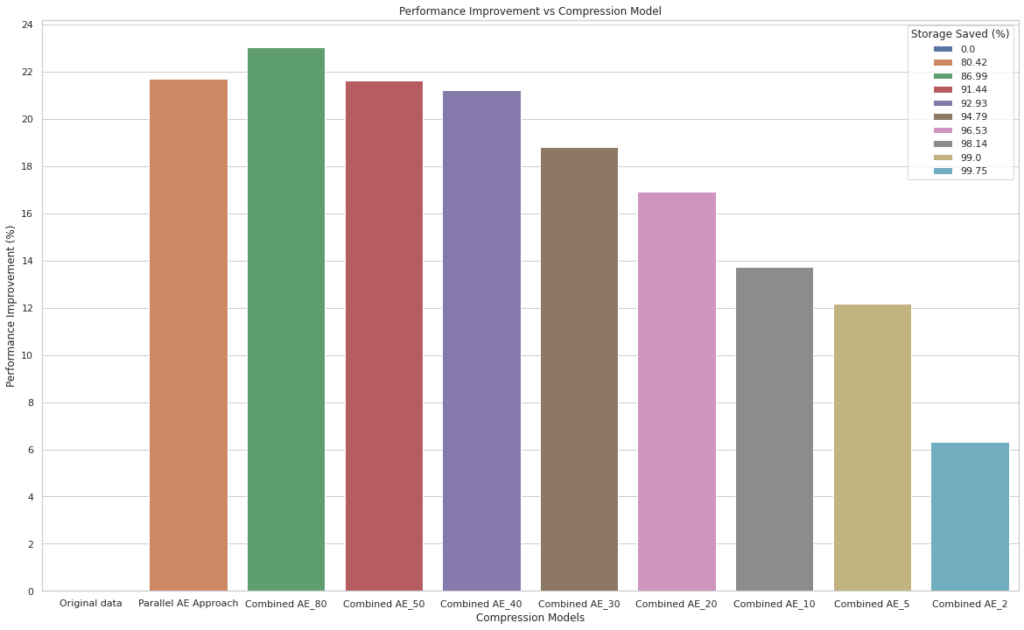

In this project, high dimensional noisy data collected from thousands of trucks during the course of 4 years was compressed using Artificial Neural Networks (ANN). This compressed meaningful information was used for performing predictive maintenance on turbochargers. Our novel deep learning ANN architecture, compressed vehicle data by over 87% while still improving fault forecasting prediction by 23% and even with extreme data

size reduction of 99.7% we still see a significant performance improvement of 6.31%.

We developed a neural network model called learned embeddings for learning multi-dimensional relationships between sensor readings and categorical features. The Embedding model was able to understand the properties of various trucks and group similar trucks together. In this way, our model can filter out vehicles that tend to break down more than others and find out what are the causes of those faults. With our model, we are able to make a fault prediction with an accuracy ≈ ± 5 months (155 days). (accuracy calculation based on MAE scores).

Fault Forecasting Performance Result Table – RUL (Remaining Useful Life)

| Model | MAE of RUL prediction |

| Mean Time to Failure (Baseline) | 230.81 |

| Best Numerical AE model | 156.35 |

| Best Categorical AE model | 148.51 |

| Parallel Stacked model | 145.74 |